EVAFORCE® MENU

EVA Film for Laminated Glass

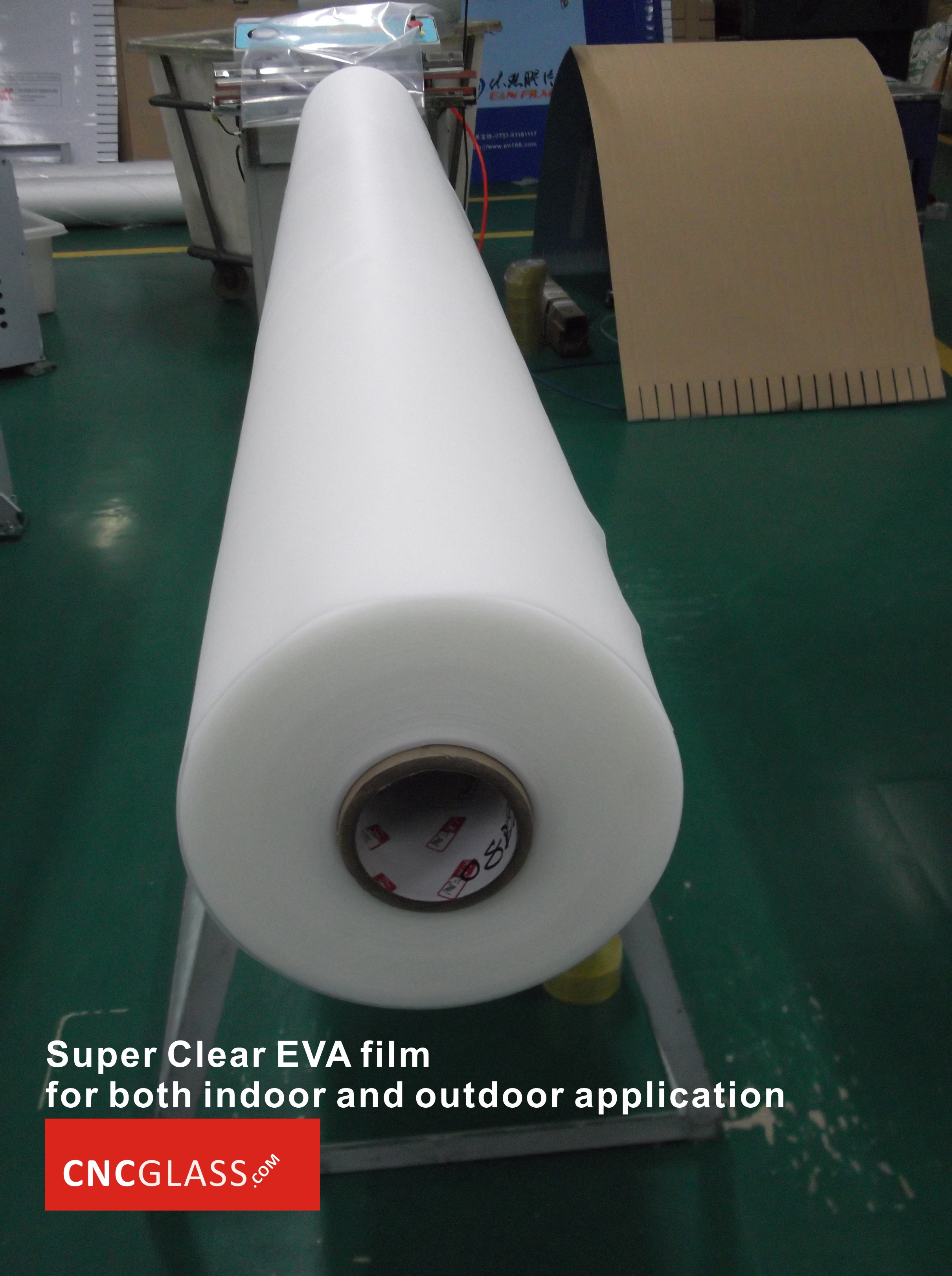

CNCGLASS Producing Line

EVA Film Loading Container

EVA Film Technical Datasheet

CNC EVA Film Super Clear External Type for Safety Laminated Glass by Peter Lin

Ethylene-vinyl acetate EVA Interlayer Film for Laminated Glass

EVA Film:

EVA stands for ethylene vinyl acetate, a copolymer resin used in the production of laminated glass as the interlayer sandwiched between two pieces of glass. The main function of the interlayer is to stick the two piece of glass together, in order to make the sandwiched glass safer and more secure.

EVA Film is made out of macromolecule material and it performs excellent in bonding strength, heat resistance, cold resistance, humidity resistance and tensile strength in laminated glass. It has been partly taking the places of PVB film in laminated safety glass, laminated art glass, laminated color glass.

EVA film is not adhesive before heating. After heating, it melts and reacts. In the production of laminated glass with EVA interlayer, no autoclave, roller press, air bag, or vacuum rubber ring is required. As EVA interlayer can be processed under normal climatic conditions, no clean room with climatic control is required. And the producing machine of laminated glass with EVA Film is less cost and easier to process.

Laminated Glass with EVA Film

Laminated Glass with EVA Film is an important kind of laminated glass in glass industry .The processing principle of EVA laminated glass is similar to most of the laminated glass . Furthermore, using EVA film to laminating glass does not require autoclave. All laminating processing will be finished and completed in one vacuum laminator. EVA Film for laminated glass has excellent transparency, outstanding adhesion and aging-resistance (more than 15 years), can be used for architectural glass, decorative glass with fabric, privacy glass, auto glass etc.

Advantages of EVA film :

– High tensile strength

– Excellent transparency

– Outstanding adhesion

– UV protection

– High impact resistance

– Good temperature withstanding

– Water proof

– Humidity durable

– Long-term reliable (long-term aging resistance)

– Sound barrier

Names of EVA FILM for Laminated Glass

Some will call EVA Film in different name:

-laminated glass eva interlayer

-ethylene vinyl acetate film

-solar eva film

-glass lamination film

-glass laminating film

-laminating film rolls

-lamination film

-safety glass film

-tempered glass film

-security glass film

-glass eva film

-laminate film

-security laminate film

-decorative glass film

-stained glass film

EVA FILM Category

Based on the UV Blocked rate, the EVA FILM can divided into :

Indoor EVA FILM and Outdoor EVA FILM.

Indoor EVA FILM, of course, the UV blocked rate is lower than 50%. So they can only be used inside building.

But how is it going to happen, if I put the indoor EVA FILM laminated glass in outdoor using?

The indoor EVA FILM laminated glass will turn yellow in short period, maybe two years, and bubbles will come out inside the laminated glass, and the EVA FILM will break away from the glass.

For outdoor EVA FILM, the most advanced EVA FILM can absorb 99% of the UV radiation.

But at least the UV radiation should be absorbed more than 85% percent to be implied for outdoor.

Yes, it’s not necessary to say but I want to mention that you can use the outdoor EVA FILM for indoor.

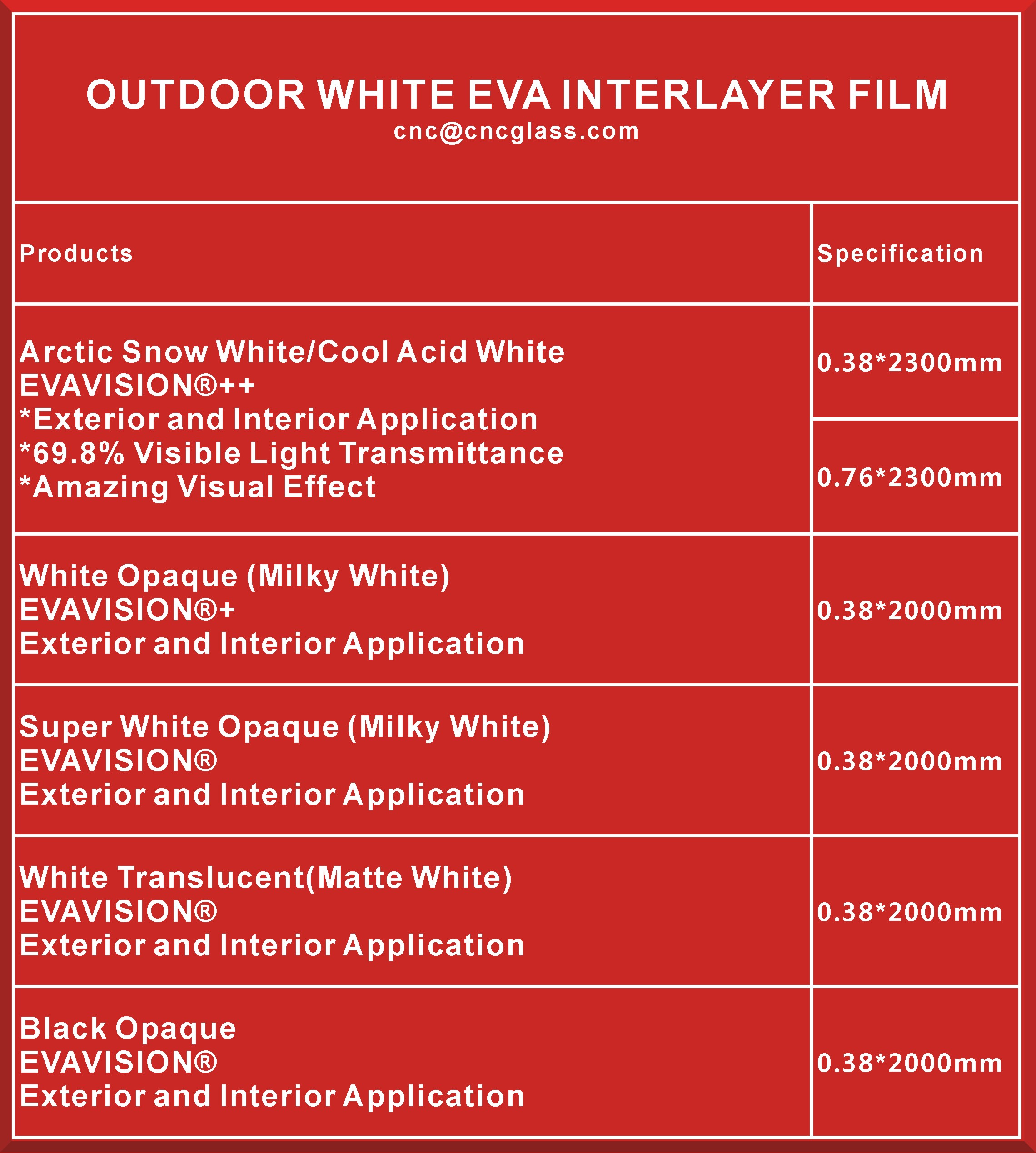

Based on colors, EVA FILM can divide into:

-no color transparent

-colored transparent (standard 8 colors in China)

-colored translucent (standard 7 colors in China)

-colored opaque

-Black (transparent, translucent, opaque)

-white (transparent, translucent, opaque)

The standard colors are:

RED/DEEP GREEN/GRASS GREEN/BLUE/LEMON YELLOW/ORANGE YELLOW/PURPLE/PINK

Based on thickness, the EVA FILM can divide into:

(CNCGLASS produces 0.38mm and 0.76mm.)

0.38mm

0.76mm

Testing UV Radiation Reststance Properties of Glass Laminated EVA Film by Peter Lin

EVA Shower Door Glass

EVA Glass Building:

EVA Glass Floor

EVA Glass Partition

EVA Glass Curtain Wall

EVA Glass Railing

EVA Laminated Glass for Residential Building

Package: